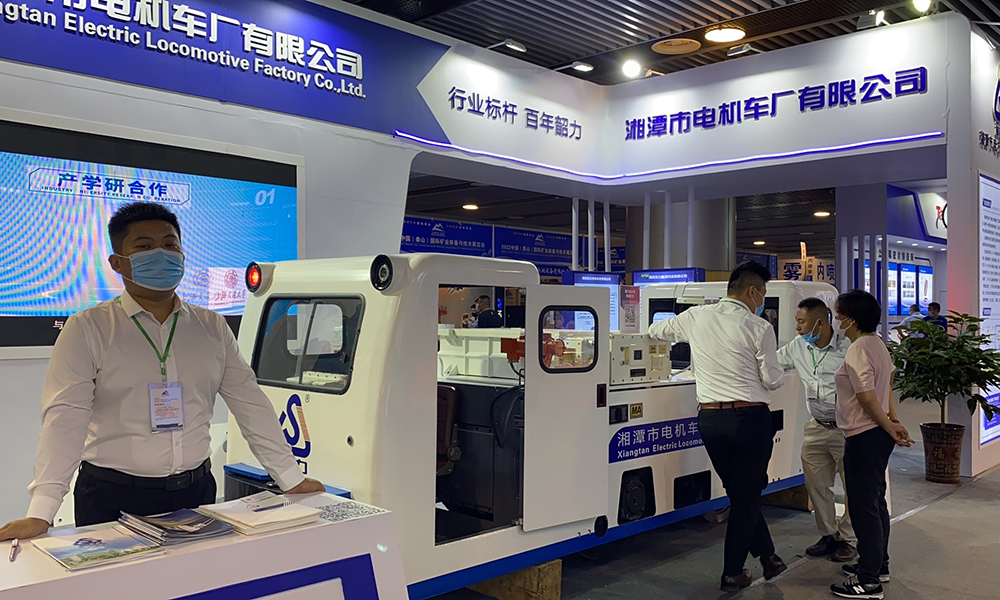

COMPANY PROFILE

Hunan Shaoli Group Electric Co., Ltd. was founded in Xiangtan City Hunan Province in 1995.

Our brand "SHAOLI" is a well-known trademark in China. The self-made ratio of our products exceeds 90%, and both motors and lead-acid batteries are produced by ourselves. We are the only electric locomotive manufacturer in China that produces its own motors and batteries. The products have obtained ISO9001, ISO45001, OHSMS, CE certification. We have independent intellectual property rights of domestic leading technologies such as IGBT step-less speed regulating systems, hydraulic drive systems, AC variable frequency converters, dual-motor traction control system, unmanned driving control system...

HOT PRODUCTS

Mining and Tunnel Battery Locomotive

Frame

Constructed in welded steel and suspended by spring on grease bearing seats with tapered roller bearings.

Speed control

In order to achieve continuous and stepless speed regulation, they have an electronic speed controller with high reliability.

Brakes

Mechanical drum brake to the coupler.

Mining Trolley Locomotive

Frame

Constructed in welded steel and suspended by leaf spring or rubber studs on grease bearing seats with tapered roller bearings.

Speed control

In order to achieve continuous and stepless speed regulation, they have an electronic speed controller with high reliability.

The AC converters convert the DC from trolley line into AC and the controller adjusts the speed of AC motors by the power frequency of the AC converter.

TBM Latter Mating Equipments

Mortar truck

Mortar truck is composed of running gear, car body, power transmission system, mixing system, electrical control system and other parts. The mixing motor, gearbox and mixing shaft are directly connected, and the structure is compact. The running device adopts a two-axle with axle box, and it is a bearing mechanical transmission without bogie. The power system adopts two-stage speed reduction box. The stirring shaft system can realize clockwise and counterclockwise rotation. The seal of the mixing shaft at both ends of the vehicle body is a labyrinth seal, and the mixing shaft can be taken out and replaced as a whole.

Mine Wagon

Bottom unloading mine wagon

It is mainly composed of box, frame, buffer, connector, axle and so on. When using it, an unloading station should be set up in the underground wagon yard, and there is an unloading pit in the unloading station. When the wagonriage of the mine wagon is suspended and moves forward along the idler rollers, the bottom frame of the mine wagon automatically opens downward by its own weight and the weight of the ore it wagonries, and the unloading wheel at the rear end of the wagonriage bottom frame rolls down along the unloading curved track, and the bottom of the wagon rolls downward. The door gradually opened. Due to the weight of the loaded ore and the self-weight of the underframe of the minewagon, the minewagon is subjected to a horizontal thrust, which pushes the locomotive to move forward.

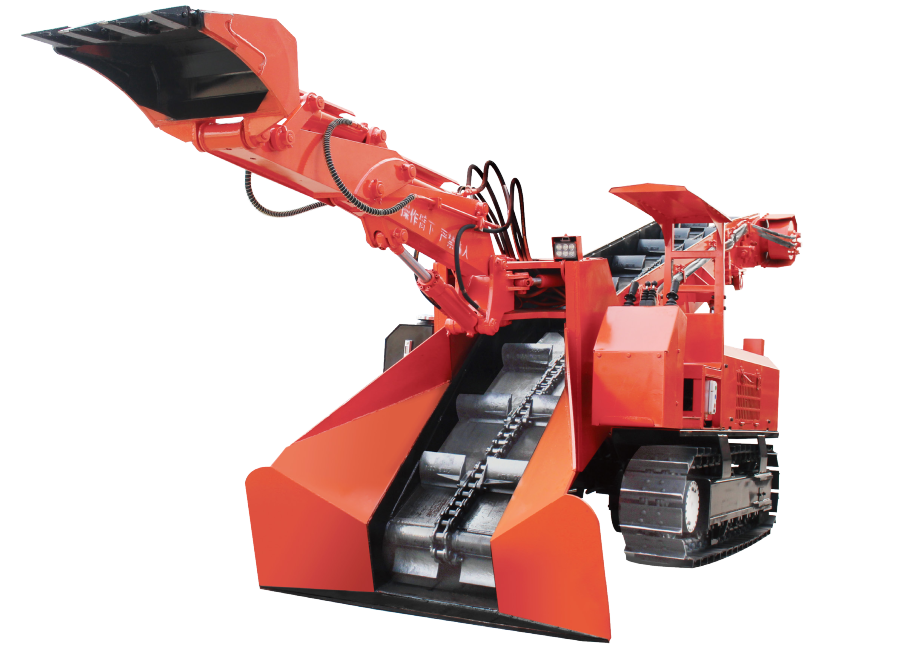

Mucking Loader

Crawler Chain Mucking Loader

Model: ZWY-1.7M-80T-DQLGF

Loading capacity: ≤80m³/H

Dimension: 6750*1820*2060MM

Weight: 7100±200KG

Minimum turning radius: ≤3R

Digging width: 4100mm

Gallery

English

English Español

Español Русский

Русский